Introduction

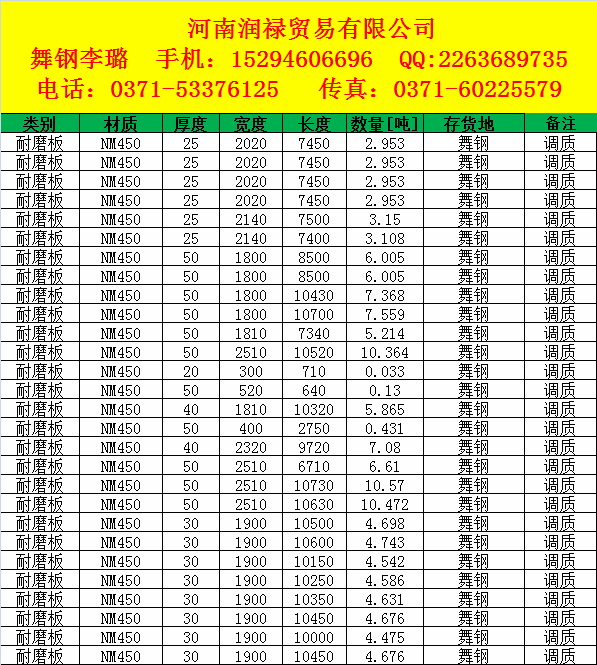

1 range

1.1 the standard stipulates the size, shape, technical requirements, test methods, inspection rules, packaging, marking and certificate of quality of the steel plate used in the blast furnace shell.

This standard is suitable for steel plate of furnace shell with thickness of 8mm-200mm. The applicable thickness of each brand is shown in Table 1.

Table 1

Standard maximum nominal thickness for grade standard, mm use

BB503C

200 blast furnace shell

BB503D

One hundred and fifty

BB503E

One hundred

1.2 the grades in this standard are divided into 2 strength levels according to the standard tensile strength, and the minimum tensile strength of the standard is respectively

400MPa, 490MPa.

2 Standard Dance (WJ)

3 size, shape, weight and allowable deviation

3.1 thickness deviation

The negative deviation of the thickness of steel plate is limited to -0.25mm, and the thickness tolerance Belt should be in accordance with the regulations of GB/T709.

The 3.2 steel plate is delivered on the theoretical weight. The nominal thickness plus its corresponding thickness additional value is taken as the theoretical thickness and thickness additional value. The formula is: thickness added value (mm) = (tolerance zone /2) -0.25.

3.3 the other should be in accordance with the provisions of GB/T709.

4 technical requirements

4.1 grade and chemical composition

4.11 brand

According to the impact temperature, the BB503 in this standard is divided into three quality grades of C, D and E with corresponding quality grades, such as BB503D.

The 0 grade and chemical composition of 4.12 steel (smelting analysis,%) should be in accordance with table 2 of the specified table 2

Grade

C

Si

Mn

P

S A1 (whole)

Nb

V

Ti

Mo N (PPM)

BB503C BB503D BB503E

Zero point one two

-

Zero point one eight

Zero point three zero

-

Zero point six zero

One point two five

-

One point six zero

Less than or equal to

Zero point zero two zero

Less than or equal to

Zero

Fifteen

Zero point zero one zero

-0.05

Zero

Zero point zero one

0-

Zero point zero four

Five

-

-

Zero point zero zero eight

-

Zero point zero three five

-

-

Less than or equal to

One hundred

4.1.2.1 when the [N] in molten steel like failure, allows the finished sheet to take samples at [N], [N] = 110ppm

4.1.2.2 when chromium, nickel and copper are used as residual elements, their content should be not more than 0.30%, and the sum should not be more than 0.60%.

The permissible deviation of the chemical composition of 4.1.3 finished steel sheet should conform to the corresponding provisions of GB/T222

4.2 smelting method

Steel should be smelted by electric furnace + outside refining. The steel liquid must be treated with VD vacuum degassing. All of the steel grades are composed of sedation steel.

4.3 the delivery state of each steel plate in the state of delivery shall be in accordance with the provisions of Table 3

Table 3

Grade impact temperature / centigrade thickness /mm delivery state

BB503C

Zero

8~50 control or normalizing

50~200 normalizing

BB503D

-20

8~40 control or normalizing

40~150 normalizing

BB503E

-40

8~100 normalizing

4.4 mechanical properties and technological properties

The mechanical and technological properties of 4.4.1 steel plate should be in Table 4, table 4.

The thickness of /mm tensile test impact test Charpy V 180 or bending test

B=35m

M

Yield strength

tensile strength

Elongation impact power Akv, J, longitudinal

0 C

-20 C

-40 C

Normal atmospheric temperature

Less than or equal to 16

More than 325

490-61

Zero

More than 21

More than 47

More than 47

More than 47

More than 34

D=2a

> 16-40

More than 315

D=3a

>

40-100

More than 295

>

100-150

More than 285

More than 20

Note: 1) B is the width of the pattern, the D is the center of the bend, and the A is the pattern thickness

2) the impact temperature of grade C steel is 0 C, and the impact temperature of grade D steel is -200 degree C, and E grade steel corresponds to the impact temperature of -40 degree C.

4.4.1 Charpy impact (including aging impact) according to a set of three specimens of the arithmetic mean value is calculated, allowing one sample single value is lower than the values specified in Table 4, but not less than the specified value 70%.

4.4.2 of thickness less than 12mm steel Charpy impact test (V gap) should use the auxiliary specimens, 6mm-8mm

The size of the steel plate is 5mm*10mm*55mm, and the test results shall not be less than 50% of the specified value of Table 4;

The size of the steel plate of 8mm-11mm is 7.5mm*10mm*55mm, and the test result shall not be less than the specified value of Table 4.

75%.

When 4.4.3 is strain aging, the tensile strain is used, and the residual stress of BB503 (CDE) is 5%.

4.5 ultrasonic inspection

Less than 100mm thickness, testing standard for GB/T2970 or JB/T4730.3, indicating the qualified level in the contract; thickness over 100mm, testing standards for SEL072, 3 for grade.

4.6 surface mass

The surface quality of the steel plate shall be in accordance with the corresponding regulations of GB/T3274.

5 test method

The inspection items, the quantity of sampling, the method of sampling and the method of sample of each batch of steel plate shall be in accordance with the provisions of table 5. Table 5

Sample method sample method for sampling quantity of inspection items

Chemical analysis 1 (each furnace)

GB/T222

GB/T223

Stretch BB503

One

GB/T2975

GB/T228

Bend

One

GB/T2975

GB/T232

Charpy impact

Three

GB/T2975

GB/T229

Failure impact

Three

GB/T2975

GB/T4160

See 4.5 by ultrasonic flaw detection

6 test rules

6.1 each plate of steel should be made up of steel plates of the same furnace number, same grade, same thickness, and the same delivery state. Each batch of steel plates should be weighed.

Not more than 40 tons, controlled rolling state delivery, the weight of each batch is not more than 25 tons.

Results 6.2 Charpy impact test (including aging impact) does not meet the requirements, from the same plate and a group of three specimens, six specimens of the two groups before and after the average value shall not be less than the specified value, which allows the two sample value is less than the specified value, but less than the specified value of the sample with only 70% allow.

6.3 the reinspection of other inspection items of steel plate shall be in accordance with the provisions of GB/T247.

Additional instructions: this standard is put forward by Wuyang iron and Steel Co., Ltd.

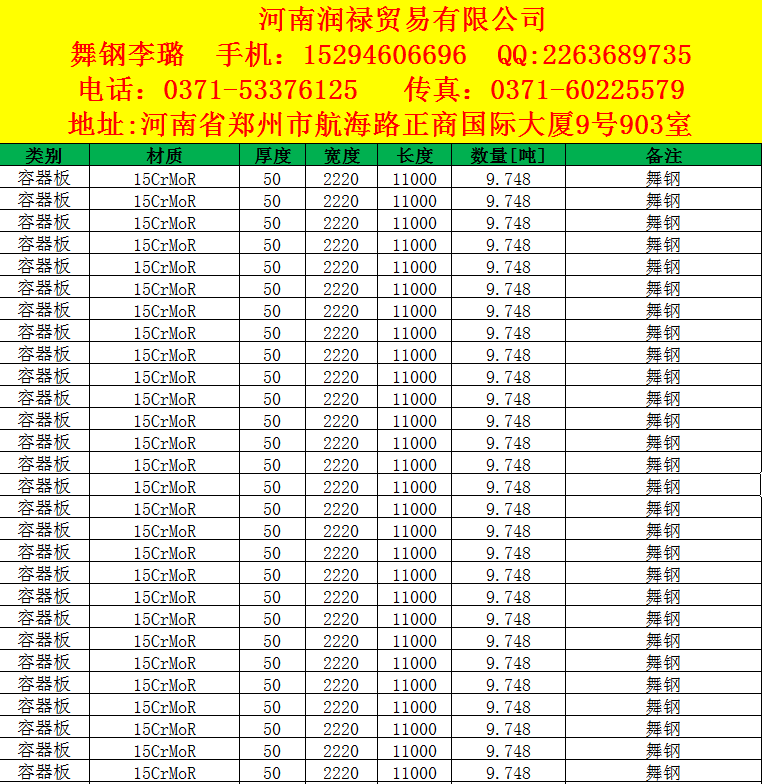

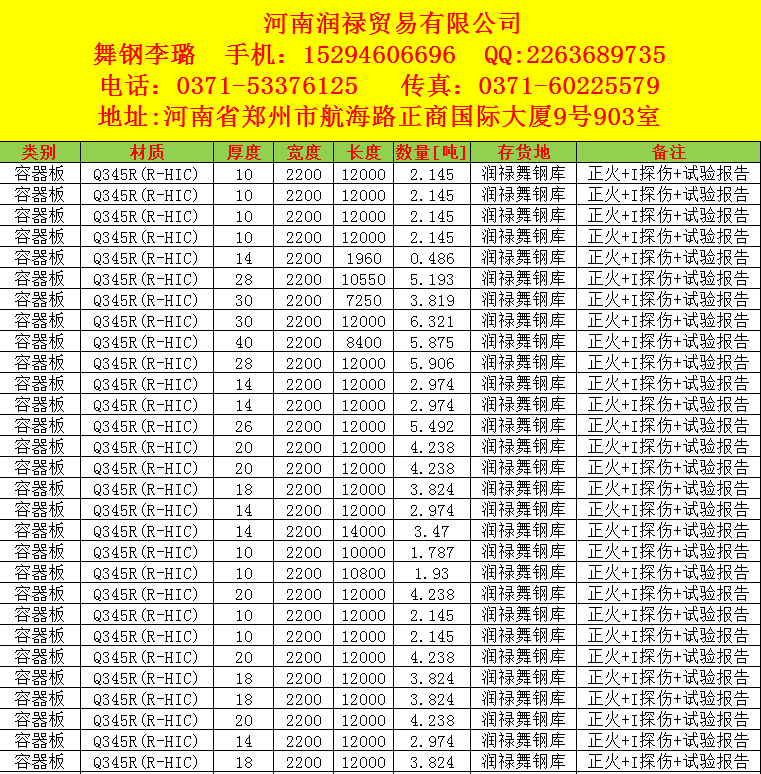

Li Lu 15294606696 / 0371-53376125

More Products

Chinese

Chinese English

English